General Electric Gas turbines and electric drive power and propulsion systems have been proven to meet the most demanding needs of the world’s navies.in MADEX International Marine Industry Defense Exhibition, GE is emphasizing its power and propulsion capabilities because they apply to two new and proposed South Korea (ROK) naval programs: KDDX destroyers and CVX aircraft carriers.

“GE is the only company in the world that provides a full range of gas turbine and electric drive propulsion solutions, including mechanical drive, hybrid electric drive or integrated full electric propulsion. Together, GE Aviation Marine and GE Power Conversion provide 41 navies on 755 ships. To improve naval power and propulsion systems,” said Kris Shepherd, vice president and general manager of GE Aviation & Shipping in Avondale, Ohio. “So far, GE has provided 155 marine gas turbines to the Korean Navy for 91 ships. Our long-term domestic partner Hanwha Aerospace Co., Ltd. jointly manufactures engine components for the Korean Navy and industrial gas turbines, and assembles, tests, and Provide service support for GE Navy engines,” Shepherd added.

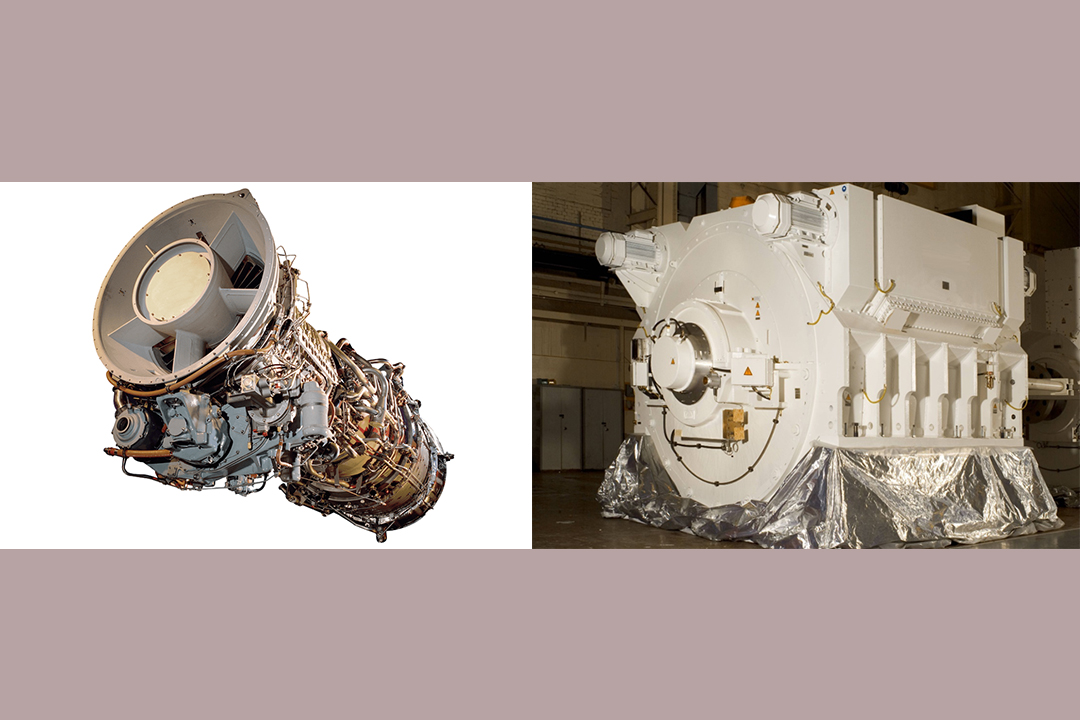

For the 6,000-ton South Korean Navy’s KDDX destroyer, GE has provided mature solutions for two considered propulsion configurations: Integrated All-Electric Propulsion (IFEP) or Hybrid Drive (HED). GE’s IFEP system will be almost identical to the British Type 45 destroyer, and will utilize other successful electric ship systems designed by GE for the Royal Navy’s Queen Elizabeth class aircraft carrier and the U.S. Navy’s Zumwalt destroyer. GE’s HED system will use 3.4 MW shock test motors designed for the British Type 26 frigate, the Royal Australian Navy and the Royal Canadian Navy’s global warship programs. Both propulsion systems will use dual GE gas turbines to meet the requirements for versatility, reliability, survivability and efficiency.

“GE has the world’s leading and proven IFEP and HED system solutions, which can now be used to support the KDDX program. We believe that the IFEP solution has significant advantages because it can easily meet the energy needs of future weapons and radar systems Growth,” said Andy Cooper, UK managing director of GE Power Conversion. “Through GE’s flexible grid power supply on board, IFEP provides other advantages, including greater operational and mission flexibility, as well as better energy management and energy efficiency,” Cooper said.

GE’s IFEP solution uses fourth-generation advanced induction motors, anti-vibration drives and GE generators—combined with reliable GE LM series gas turbines—to provide a low-risk, fully compliant solution. The KDDX IFEP solution uses GE’s advanced electric ship architecture and electrical system integration expertise, and is the natural first step for the Korean Navy to gradually expand the IFEP system on a larger CVX aircraft carrier.

MADEX highlights

During MADEX, GE’s highlights include these power and propulsion capabilities, as well as recent product enhancements that benefit the Korean Navy’s KDDX and CVX aircraft carrier programs:

Proven and proven products

- GE is the only company with appropriate expertise in naval electric drives and has 14 navies worldwide. GE can provide mature and technologically advanced electric ship propulsion equipment.

- GE is the world leader in naval IFEP solutions and can take advantage of past projects, including the Royal Navy’s Type 45 destroyers and Queen Elizabeth class aircraft carriers, and the U.S. Navy’s DDG 1000. Similar technology is being considered for the US Navy’s large Surface Combatant DDG(X) program.

- GE’s IFEP solution provides superior operational flexibility and fuel economy, power for future mission system growth, and optimal survivability/redundancy through the use of two flexible, appropriately sized gas turbines.

- For nearly 30 years, GE has been supporting the Royal Navy with HED technology; cooperation includes the pioneering Type 23 in the 1990s and the HED system now used in Type 26 city-class ships and global combat ships.

- GE has provided more than 1,500 delivered engines to the global navies and 95% of the activated propulsion gas turbines for the U.S. Navy and Coast Guard combat fleet.

- GE has 10 gas turbine service and support stations worldwide, one of which is located in South Korea.

Korean Industrial Capability

- Since 2011, Hanwha has been manufacturing engine components, assembling, testing, and providing service support for GE Aviation Marine naval engines in South Korea.

- GE engines have important local components and provide services locally, so there is no need to ship gas turbines overseas.

- Hanwha has partnered with GE Power Conversion to provide marine electric drive equipment and support.

- GE, through its Korean and global teams, has extensively cooperated with the Korean shipbuilding industry on commercial and naval ship projects, contributing GE’s expertise in managing, delivering, and helping to reduce the risks of major innovative projects.

Technology investment

- Complementing its design and engineering capabilities are GE’s marine electrical test facilities. This is the only commercial land-based facility in the world that can conduct comprehensive, full-load testing and simulation of integrated naval systems and ship architecture.

- GE’s power-intensive marine gas turbines provide first-class reliability and low life cycle costs. Compared with its steel predecessor, the new gas turbine module has reduced weight by more than 2,000 kg, eliminated corrosion, reduced noise by 60%, and reduced wall temperature by -3 to 10 degrees Celsius.

- GE’s series of digital solutions, including its Connectix Operations+ suite, provide enhanced asset performance management to support improved asset health and energy efficiency.

Global support

- Through the use of General Electric engines, the South Korean Navy will have excellent interoperability with the U.S. Navy surface warships deployed in the Pacific theater and other common allies.

- GE’s LM2500 gas turbine has a quick start function, easy onboard maintenance, and excellent global fleet performance, with a reliability of up to 99% and an availability of over 98%.

- GE’s split compressor and power turbine design allows on-site maintenance, usually without the need to disassemble the gas turbine; the Navy saves millions of dollars and weeks/months of ship unavailability every year.